The Miata track car project is making progress.

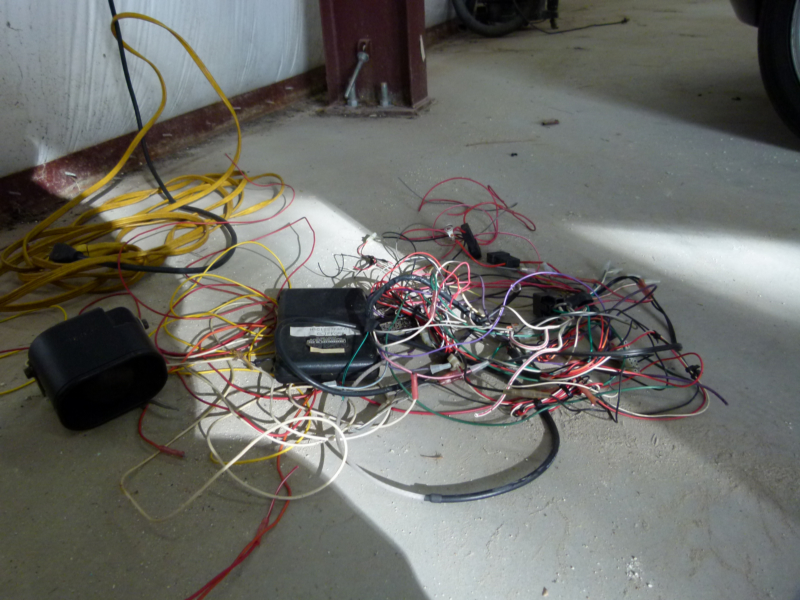

One of the first things to accomplish was to remove the aftermarket anti-theft system that had been installed in the car. The last thing I needed was to have the anti-theft system acting up so the best thing was to get it out of the car. The tough part of removing these systems is that they are integrated into the stock wiring to the degree that they are much like a tumor. You have to be careful how you remove all the pieces and keep the integrity of the stock wiring harness intact. It is a slow process and not a lot of fun.

After many hours all the wiring and equipment was dissected and removed. The test would be that the car still started and ran normally. It did!

With that out of the way it was time to get the car up in the air and start tackling some of the mechanical bits.

The rear differential is made up of an aluminum and cast steel housing. While this car is relatively rust free it has 150,000 road miles and the cast steel looked rusty and flakey and the aluminum casting looked corroded and has a white powdered look to it.

Most of the rear suspension had to be removed to get the rear differential out. That was fine since all the bushings were going to be pressed out and replaced with Energy bushings. All the eccentric alignment bolts are being replaced with new so they were unbolted and removed.

When items that were going to be reused were rusty they were thrown in a bath of Metal Rescue. It is a great product to use since it only attacks rust. It is water based and is biodegradable. It is safe to use without gloves although it doesn’t hurt to wear them. You can get most parts clean of rust in two to four hours of soaking, but the hard stuff may take over night. It can be used over and over again.

For stuff that is too big to soak in a plastic container of the stuff I use Rustoleum’s rust converter. It sprays on. I just get off as much flaking as I can with a wire brush and then the rust is converted to a paintable surface that stops the rusting. Then I can cover that with paint.

Another task was to get the differential bushing out so they can be replaced with Energy bushings. An air chisel did the trick of getting the old, pressed in rubber mounts.

The bolt-in plates had to have the rubber removed by heating and then prying with a putty knife. You have to be careful not to burn the rubber, just get it hot enough so that the bond between it and the steel is corrupted and the putty knife can do the rest. After the rubber was removed it was held on a wire wheel and all the remaining rubber was brushed off along with the inevitable rust. Once bare the metal was allowed to soak in Metal Rescue before it was taken out, dried and given a coat of primer. A couple of hours later they received their coat of satin black.

There is a lot more work to be done. Now is a good time to replace the axle boots and replace the axle seals in the differential housing. It will require a fixture to push out the axles from the rear hubs and then the assemblies can be rebuilt.

More to come.

Leave a reply to Jim’s sister Cancel reply