Many times the modifications that take place on the Miata are pretty cut and dried. One item is unbolted and the replacement is put back in its place. It takes time and a little care, but no reengineering required.

Then there are times when a modification requires additional thought and preparation in order to ensure that everything works properly and in harmony with each other.

The front sway bar (anti-roll bar) is one of those pieces of the puzzle that requires a bit of work. For one thing, the design of the factory brackets that support the mounts on this Miata are a bit flimsy. They work well enough with the standard bar and in most street driving, but they are a known point of failure when the car is tracked with a larger sway bar and very sticky tires are employed.

There are a couple of aftermarket solutions out there. They work very well, but their cost can range from $50 to $150 or more. Fortunately Mark has fabrication and welding skills so he listened to my concerns and came up with a great solution that will keep the sway bar secure and not even dent my budget.

He reenforced the existing brackets with strategically placed and welded angle iron.

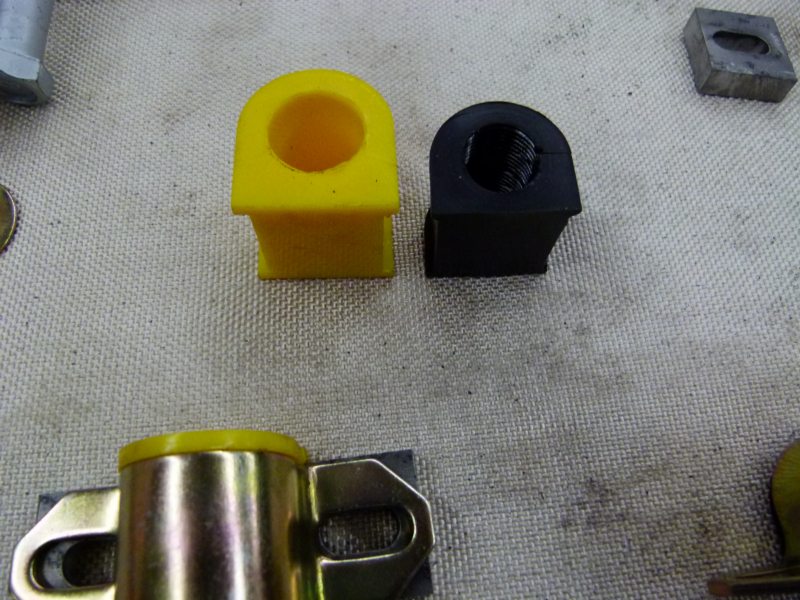

The stock front sway bar is being replaced with a 24mm bar from Whiteline out of Australia. It comes with new brackets and polyurethane bushings. And there is another engineering challenge to deal with.

Because the new bar has a greater diameter than the stock one, the bushing in which it mounts is taller than the stock bushing.

In the past I would have just cranked down on the mounting bolts until the metal bracket was secure and compressed the heck out of the new bushing. I would have done so out of complete ignorance of the fact that in doing so I had compromised the proper operation of the sway bar.

With all the clamping load required to compress the new bushings I would have just about locked the sway bar in place and inhibited its ability to rotate in the bushings, as it should. This would have resulted in unpredictable handling as the bar struggled to act as a torsion spring between the two sides of the front suspension.

With all the above in mind Mark and I put our heads together once again. The outcome was a pair of spacers that would raise and support the brackets as well as limit the compression of the bushing and allow the bar to rotate as a proper torsion spring.

All I had to do was source a longer set of bolts. Ace Hardware solved that little problem.

It is great to have clever and creative friends.

Leave a reply to mark Cancel reply